EXTRUSION BLOW TECHNOLOGY IN THE PRODUCTION OF PLASTIC BOTTLES

Plastic bottle blowing is the process of creating an empty bottle from plastic materials. This process involves heating and inflating the plastic in the form of a preform or parison. The hollow plastic part between 2 mold plates is similar to the shape of the formed product. Air is then injected to blow the plastic to expand until it touches and fits the mold shape. When the blowing process is complete, the product is cooled, ejected, and the excess trimmed in preparation for secondary manufacturing processes.

There are two main types of blow molding: injection blow molding and extrusion blow molding. The main difference between these two technologies is that injection blow molding creates a preform. The preform can be stored and reheated when running the blowing process. In contrast, the extrusion blow technology produces the parison and needs to run as soon as the parison is created.

In this article, Duy Tan Precision Mold Company will delve into the analysis of extrusion blow molding technology.

History of blowing technology

Plastic bottle blowing technology has its roots in the ancient glass blowing process. Melting glass and plastic can be easily formed into desired shapes. The first glass-blowing process, known as free-blowing, was created around the 1st century BC. By the first century AD, the blow mold was formed and began to replace the blowing process with the free shape.

In 1850 Samuel Armstrong patented the use of natural rubber as a blow molding material. In 1930, with the development of Plax Corporation’s first casting machine using cellulose acetate as the raw material. By 1939, low-density polyethylene (LDPE) was found and introduced by Imperial Chemical Industries from the UK. LDPE is more suitable for blow molding. By the 1950s, the blow molding industry was developed and commercialized, paving the way for today’s modern bottle-blowing technologies.

BLOW MOLDING PROCESS

The blow molding process consists of smelting, homogenizing, extruding, molding (blowing), cooling, and extrusion.

Different manufacturing plants may use added processes, such as cooling or heating cycles, and adding additives and colorants. These added processes depend on the design and intended application of the final products.

Plasticizing, melting plastic by heat:

When the plastic granules enter and pass through the screw, the extruder, the plastic is melted by continuous kneading and heating. Electrical heating elements or heating rings are wound around the extruder barrel to provide heat to melt the plastic. The extruder screw is designed to provide sufficient shear and compression to match the specification of each kind of plastic.

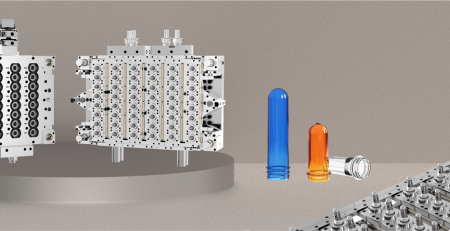

Forming plastic into a Parison or Preform

This process helps to convert plastic into the form of Parison or Preform before it comes to the dual process.

Parison clamping (molding)

The two parts of the mold plate are clamped with the parison, leaving only one hole to carry out the bottle-blowing process.

Blowing plastic

Compressed air is introduced inside the preform to inflate the parison until it fills the gaps and matches the mold walls, shaping it according to the shape of the mold.

Cooling and removing products

Once touching the mold walls, the plastic will be cooled at a predetermined rate to help stabilize the size of the product. After cooling, the mold opens and ejects the product.

Trimming, removing burrs

After the blowing process is complete, most blow molding molds will have burrs and excess plastic, so these parts need to be removed according to product requirements.

Leak testing

Leak testing is the necessary process with plastic bottles and packaging. Manufacturing plants use pressure applied to the bottle for checking. If any air is coming out or entering the bottle, this bottle needs to be discarded.

Extrusion blow molding

In extrusion blow molding, plastic is melted and extruded into a hot plastic called a parison. The parison is round, sometimes oval, and then shaped in a mold.

The extrusion blow blowing method always exists the burr part of the parison pipe outside the mold cavity, so it requires workers or an automatic cutting system after finishing the blowing process. The extrusion blow molding process consists of two technologies continuous extrusion blow molding and intermittent extrusion blow molding.

Continuous extrusion blow molding

A continuous extrusion blow molding system will have many identical molds to carry out the blowing process. Parison are created continuously during the production process. When the parison reaches enough length, it will be cut according to the mold length. After receiving the parison, the mold will move to the pre-positioned position corresponding to the clamping, cutting, inflating, cooling, and ejecting processes. The molds are continuously used as they rotate around the wheel hub.

Continuous extrusion blow molding is suitable for small volume production of plastic products, requiring less investment and less complicated operation. To manufacture larger-volume products, manufacturers must use plastics with appropriate viscosity and good heat resistance because moving between steps during blowing can cause the plastic to sag. Continuous blow extrusion is also used to blow heat-sensitive plastics such as PVC because the shorter cycle times limit the breakdown of the plastic.

Intermittent extrusion blow molding

Intermittent extrusion blow molding starts when there is enough mass of molten plastic inside the extrusion head. Plastic Parison are not produced continuously. After the plastic tube reaches enough volume, the mold will clamp to perform the bottle-blowing process. The process of forming a new parison will start when the product is finished and removed from the mold.

Since the process of blowing a product does not need to be stopped in steps, resulting in shorter process times and reduced plastic sag. Intermittent extrusion blow molding is used to manufacture large-volume products.

Intermittent extrusion blow molding can produce multi-layered or multi-colored products thanks to different Plastic channels. However, it is also necessary to pay attention to the melting temperature and the composability of the materials.

THE ADVANTAGES OF EXTRUSION MOLDING

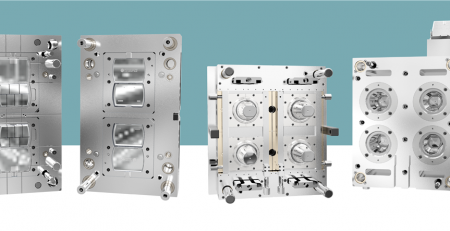

Low cost

The mold costs in extrusion blow molding are lower than in the injection molding method because of lower pressure. The machinery costs are lower as well.

Flexibility

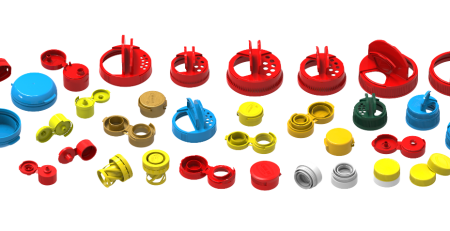

- Extrusion molding provides considerable flexibility in manufacturing products with cross-section, irregular shapes.

- Extrusion blow molding can use many different colors and types of plastic in the blowing process

Post-extrusion shape change

The plastic remains warm when it leaves the extruder, allowing for post-extrusion manipulation. Manufacturers can use a variety of rollers and dies to alter the shape of the extruded plastic to fit their needs.

THE DISADVANTAGES OF EXTRUSION MOLDING

Dimensional tolerance

When the plastic exits the extruder, it usually expands due to heat. It is difficult to accurately predict the extent of expansion because it is affected by different factors in the process.

Weak consistency

- The product does not have a uniform thickness. Plastic product is more prone to thinning in far positions.

- The corners and shoulders of the bottle are usually weaker than other positions.

Burrs removal

It is necessary to carry out the removal of burrs after the pressing process.

COMMON PLASTICS USED IN BOTTLE BLOWING

High-Density Polyethylene (HDPE)

The desirable physical properties of HDPE include chemical resistance, temperature resistance, and high strength, making it one of the most popular blow molding materials. HDPE is easily molded and is suitable for both consumer goods and industrial applications, including a wide variety of bottles and containers.

Low-Density Polyethylene (LDPE)

Compared to HDPE, LDPE is softer and more flexible. Therefore, LDPE is an excellent choice for plastic bags and flexible packaging. LDPE and HDPE share some properties, such as being chemically inert and susceptible to mildew.

Polypropylene (PP)

PP is another widely used, general-purpose molded plastic, just like HDPE. The main difference is that PP is stiffer, less dense, and resistant to very high temperatures.

Acrylonitrile Butadiene Styrene (ABS)

ABS is very suitable for packaging, containers, and other household items. However, ABS is more susceptible to chemical damage than other blow-molded plastics.

Polystyrene (PS)

PS plastic is a naturally transparent thermoplastic that is available as both a typical solid plastic and in the form of a rigid foam material. Solid Polystyrene is a hard plastic used in food containers and laboratory plastics. However, PS is very brittle, which should be noted in cases where high strength is required.

Polyurethane (PU)

PU is easy to mold and is used in industrial facilities. PU is a hard plastic and has high heat resistance.

Santoprene

Santoprene is a thermoplastic that behaves like rubber. This makes Santoprene a versatile and durable choice for applications such as household electrical appliances, medical equipment, and electronics.

Kostrate®

Kostrate® is resistant to impact and high temperatures, so it has been favored in many applications such as food preservation, beverage packaging, and toy manufacturing.

K-Resin Styrene-Butadiene Copolymer (K-Resin SBC)

K-Resin SBC is a transparent plastic with properties similar to Kostrate, including high impact resistance and hardness. So, it is a good choice for packaging, medical devices, and toys.

Duy Tan Precision Mold experts have many years of experience in the field of plastic bottle blowing mold making. Applying simulation technology to packaging production, helps products with diverse designs while still meeting strict standards in terms of optical appearance as well as bearing capacity of bottles.

Contact :

Duy Tan Precision Mold Co., Ltd

Hotline : +84 28 3754 5418 (ext. 728) | Fax: +84 28 37 54 54 16

Info@duytanmold.com | Facebook: https://www.facebook.com/KhuonChinhXacDuyTan