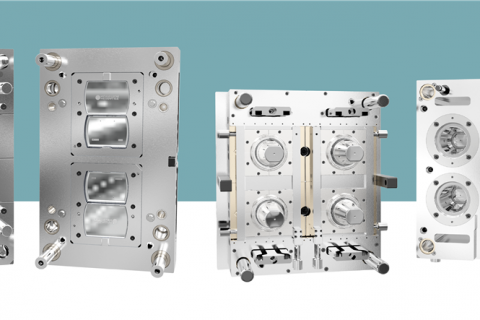

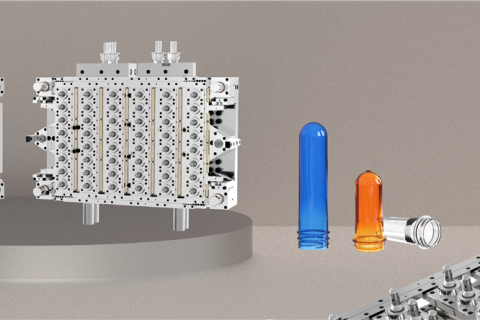

Design, processing, and production of plastic caps, plastic cap molds

HOW TO MAKE A PLASTIC BOTTLE CAP CONTAINER? Around the world, people use millions of lids every day. The lid has a variety of applications in daily life. It appears on household medicine bottles, cooking oil bottles, sauces, or helps keep water in beverage bottles. So, where and how each bottle cap is produced, please refer to the article below. BOTTLE CAP STRUCTURE A plastic cap is a part to cover an object, ensuring that the contents inside are always kept [...]